Services Sub Panel

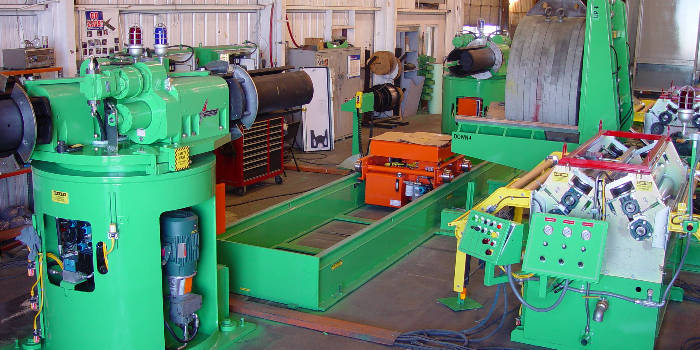

A Full Spectrum of Services

We provide total coverage for control system service and projects. We provide knowledgeable expertise in all aspects from specification to equipment buy-offs. We supervise assembly and conduct your commissioning phase through to qualification to insure your project delivers its design potential. We can stay on-site after installation to insure your facility continues to run the way you expect it to. We also provide maintenance and continous process improvement to manufacturing systems, as you, the client directs, for maximum productivity and safety. Bottom line safety combined with intelligent operator interfaces, data gathering and reporting for management gives every layer of the plant a competitive advantage. We leverage our years of experience in manufacturing control to reduce your downtime with service that gets production back up and operating quicker, through to data gathering and exception reporting for management that pin-points the most effective areas for maintenance and capital project planning.

PLC Programming

We provide PLC programming and documenting for many brands of PLCs. Whether you have the original programs or not, we can work with whatever you have and get your process back to the way you need it to run. We'll document it and back it up when we're done too.

HMI Programming

We provide HMI programming for many brands of operator interface devices from PC based packages to touch screen HMIs. No original programs? In 99% of the cases we can extract the program and reload it with the changes you need to keep you process working. And of course, it will be documented and backed up when we're done so you're getting your money's worth.

Industrial Network Support

No matter what age or state your PLC and manufacturing data network is in, we can maintain, extend or even plan with you to upgrade or replace it to get the connectivity you need to maintain PLCs and HMIs and extract data from your process.

Computer Aided Design

We can provide on-site design and as-built drawings. Our customers love having updated drawings even as the project is in progress. We can even set up your ACAD workstation in your new facility and conduct training as well. Insuring your engineering is kept up to date is money in the bank for future projects, daily troubleshooting and maintenance. If you're new to CAD, we'll show you how to do it and get your money's worth. If you're behind the 8 ball a little, we can bring you up to speed and leave you with a fully documented facility, ready for the next project.

Training

All the advantages of the best control technology are lost if your technical staff can not maintain and continue to implement productivity improvements. We can evaluate your electrical potential and provide a customized training plan based on our extensive training program framework. From PLC and Interface programming through to AC or DC drive programming and repair, we have the knowledge and depth to instruct your technical people in precisely the areas they need to know to benefit the systems they maintain.